Transducer Packaging, Reusable and Disposable Cartridge, Interfacing

Properly designed cartridges take in the diced chip and allows for handling, fluidic and electrical connections. Two different types of cartridges were tried: A reusable milled one as well as a molded version. In both versions, the single sided contact scheme allows for direct contacting through a boar5d to board connector.

The milled cartridge and a cast moulded PDMS gasket provide for the reusable cartridge. The transducer chip is put into a recess in the cartridge. The sealing gasket in this set-up performs a sealing function and no alignment or fluidic routing functions like in the advanced injection moulded version. The fluidic interface is simpler and realized by steel capillaries that are inserted into the PDMS gasket and joined with a PMMA holder. By appropriate tubing the capillaries are connected with the fluid reservoirs and with the pump. The PMMA holder is screwed to the cartridge, which is then inserted into the receiving socket.

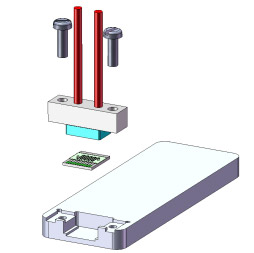

Catridge Exploded and Assembly

|

|

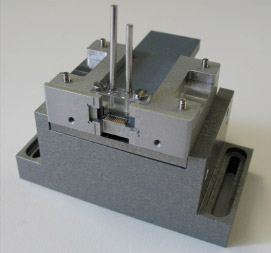

Milled reusable cartridge. Left: Assembly steps of the chip into the cartridge. Right: Photo of the assembled cartridge

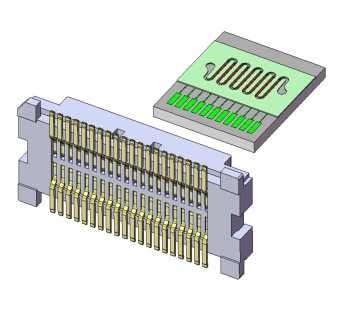

The packaged chip is interfaced with a board-to-board receptacle in a way that direct contacts ( no wire bonding) are established between the chip contact pads and the receptacle spring contacts, which in turn establish the interconnects with the electronics board.

|

|

Direct contacting concept. Left: The chip with the single-sided contacts is inserted into a board to board receptacle so that the receptacle spring contacts will touch directly on the chip metal pads. Right: The socket that makes the precise connector-chip alignment possible. The connector is placed on the recess shown on the flat back side of the socket. The two threaded holes are for the mounting of the analogue electronics board carrying (through soldering) the board to board receptacle.

In addition to the reusable cartridge, a disposable cartridge was developed to explore the possibility of low cost packaging solutions based on moulded plastics and elastomers. Here, the moulded front side (green plastic) is held together with the back foil and the moulded gasket by welding (ultrasonic or laser).

|

|

The moulded cartridge. Left: Side view showing the green moulded plastic with the chip recess, the back foil on top and the gasket in between. Top view showing the paerimetry of the gasket and the gasket inlet and outlet holes.