|

|

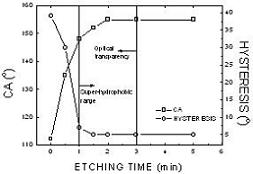

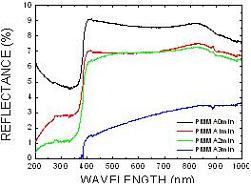

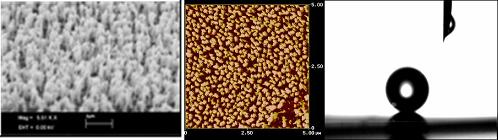

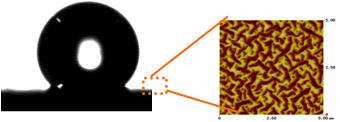

Micro and nano texturing of polymers and other materials to produce smart surfaces of tuned wetting and reflectivity Producing smart polymer surfaces by tuning of their properties is of extreme importance in nanomanufacturing, as well as microfluidic applications. It is desirable that modern smart surfaces mimic nature by being self-cleaned (lotus leaf like), antireflective and transparent etc. Such properties can be given to a surface by producing tailored dual scale micro / nanotopography, and appropriate surface chemistry. Their combination can lead to superhydrophobic or superhydrophilic and / or graded refractive index optical surfaces with minimal reflection. In this field, we explore plasma processing as a route for fast and cost-efficient nanofabrication technology. We are studying a variety of polymeric substrates (PDMS, PMMA, PEEK, etc.) and silicon with respect to their surface topography modification upon plasma exposure, and we can obtain superhydrophobic or superhydrophilic as well as surfaces of controllably defined wetting properties (from hydrophilic to hydrophobic), depending on the plasma processing details. We can also tune the transparency. Available videos:

- Superhydrophobic PDMS (see Tserepi et al Nanotechnology 2007)

- Nanotexturing and control of wetting properties of PDMS by oxygen plasma treatment. (see Tsougeni et al., Plasma Processing and Polymers 2007, Japanese Journal of Applied Physics 2007)

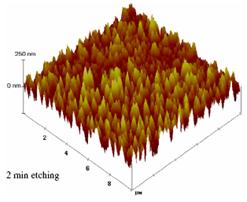

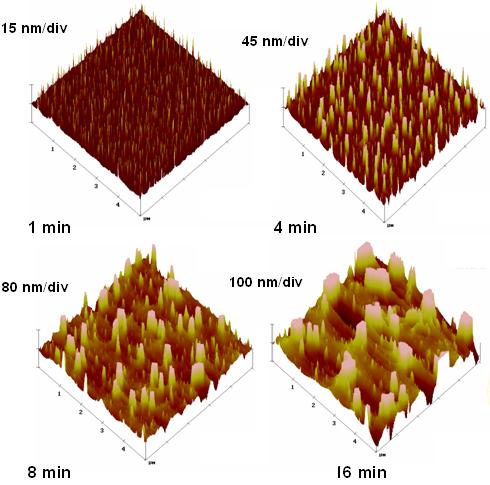

- Nanotexturing of Silicon in SF6 plasmas (G. Kokkoris et al Phys Rev B 2007) Etching of silicon in SF6 plasmas produced interesting nanotexture shown below. Although this nanotexture is small compared to etched depth (etch rate approximately 4 microns/min) it grows with time both in height and diameter.

|

|